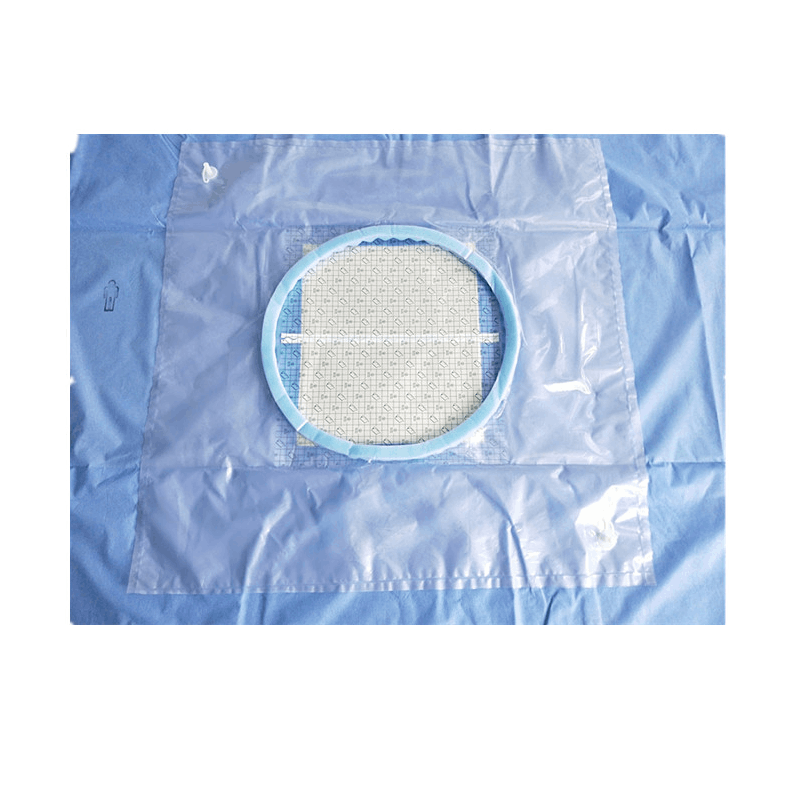

Medical isolation mask and goggles are personal protective equipment, goggles are eye protective equipment, mainly by changing the transmittance intensity and spectrum, to avoid the damage caused by radiation light to the eyes, but also can block the damage caused by the splash in the air, dust, etc...

View More

-

WhatsAPP/Wechat +86 199 5567 1917

WhatsAPP/Wechat +86 199 5567 1917 -

Email us info@medpurest.com

Email us info@medpurest.com

New Products

New Products

Leave A Mesage

Leave A Mesage